INFORMATION

- 2025-05-28 Expo

- Exhibitor Information: “JPCA Show 2025 ”

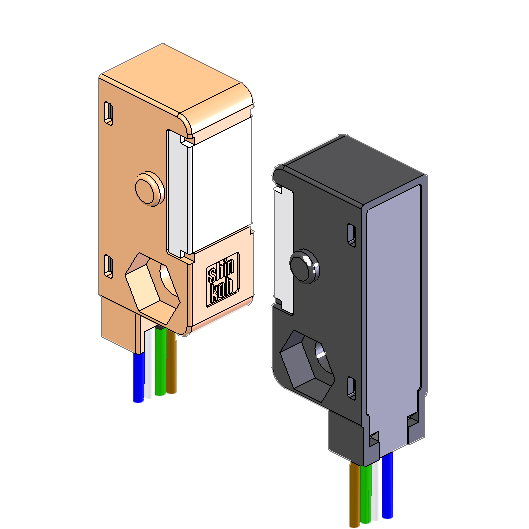

- 2024-10-29 Product

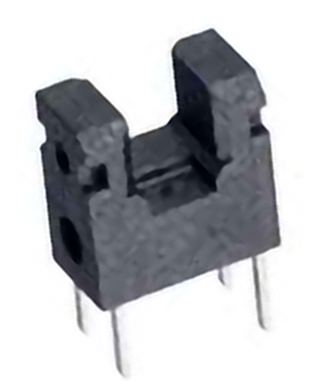

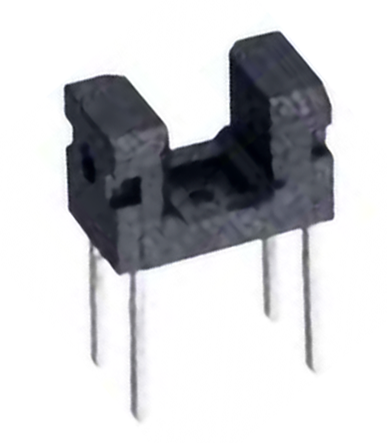

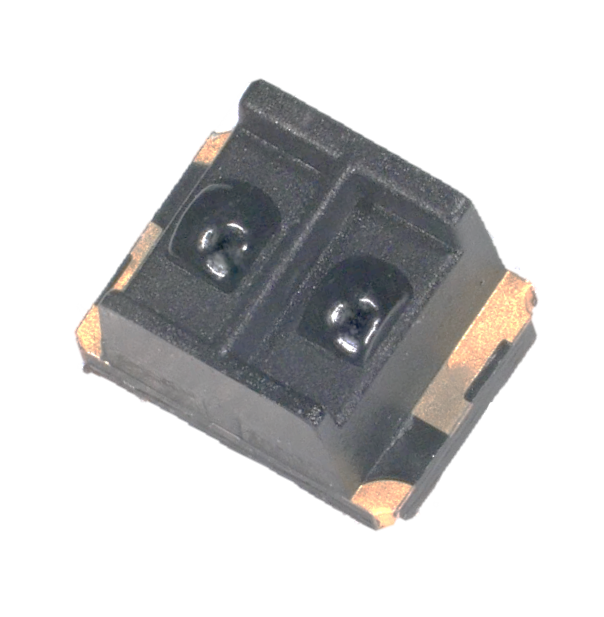

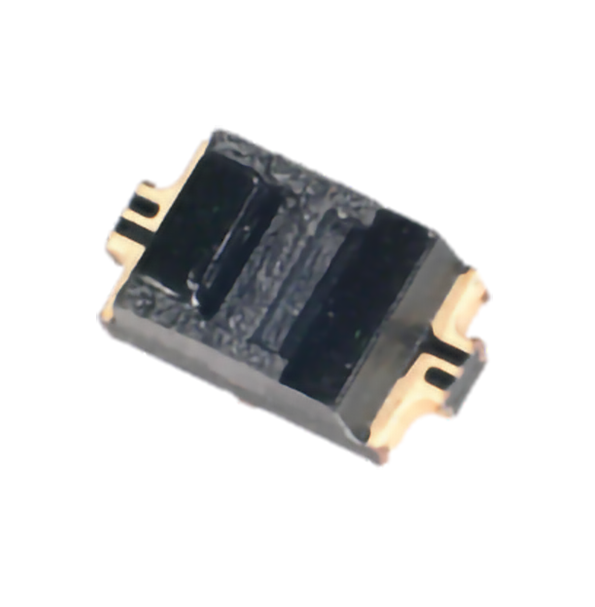

- New Product: ≪Limited Reflective Sensor≫ Motion Sensor (KM Series)

- 2024-06-30 Corporate

- The sensor site has been completely renewed.

- 2024-05-29 Corporate

- Nichia Corporation LED Sales 30th Anniversary Commemoration

- 2024-05-29 Corporate

- 50th Anniversary Website Now Open

-

Concept

Realize the bright society by shining the society with the technology of light

Our abundant life is supported by the invisible technology of light. The mission of SHINKOH ELECTRONICS CO.,LTD.. is Providing products which can be light of hope and creating prosperous future for all.. With our experience and know-how that we have cultivated since our founding, we provide high-quality and high-precision products and we also support you to solve your problems with our high technical expertise and adaptability.

-

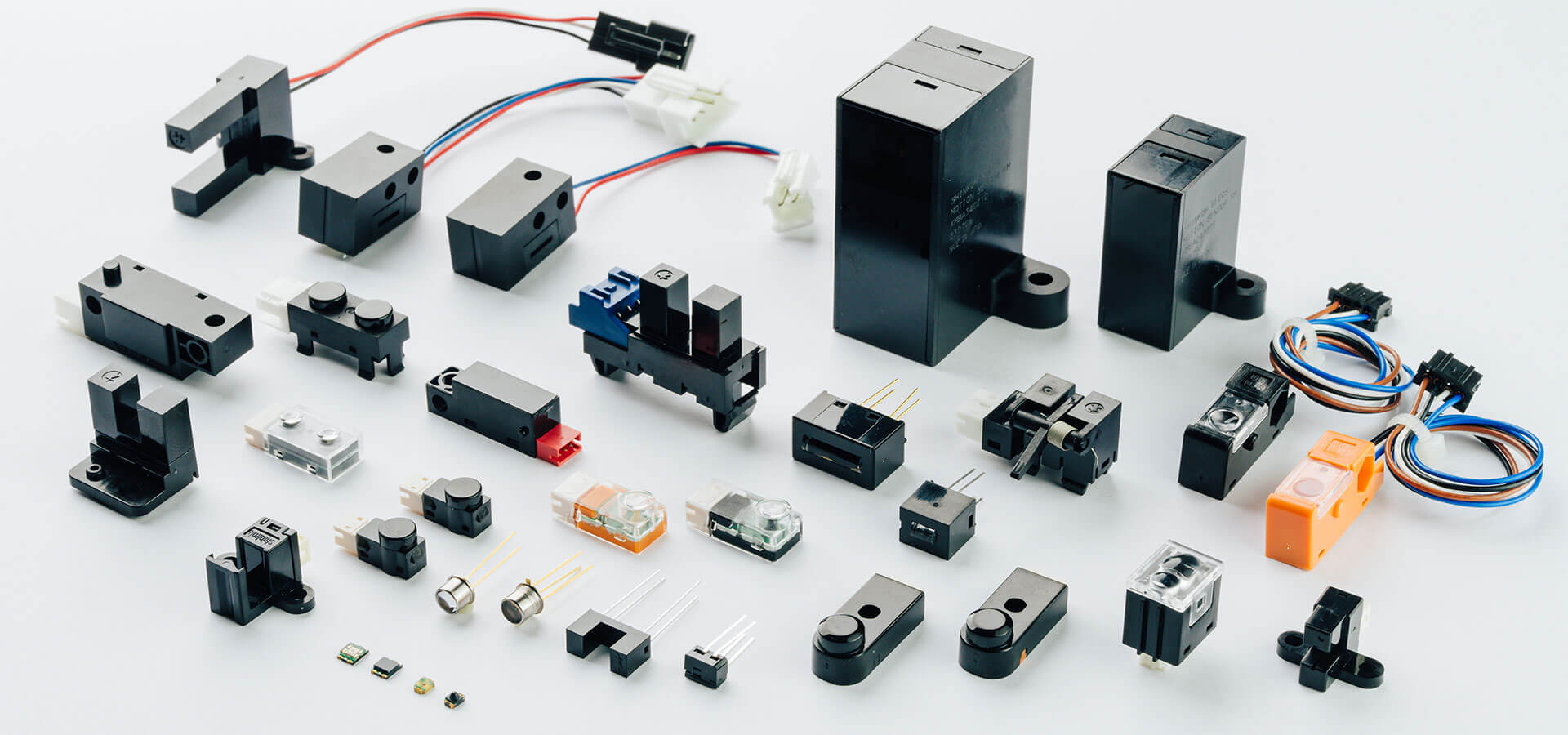

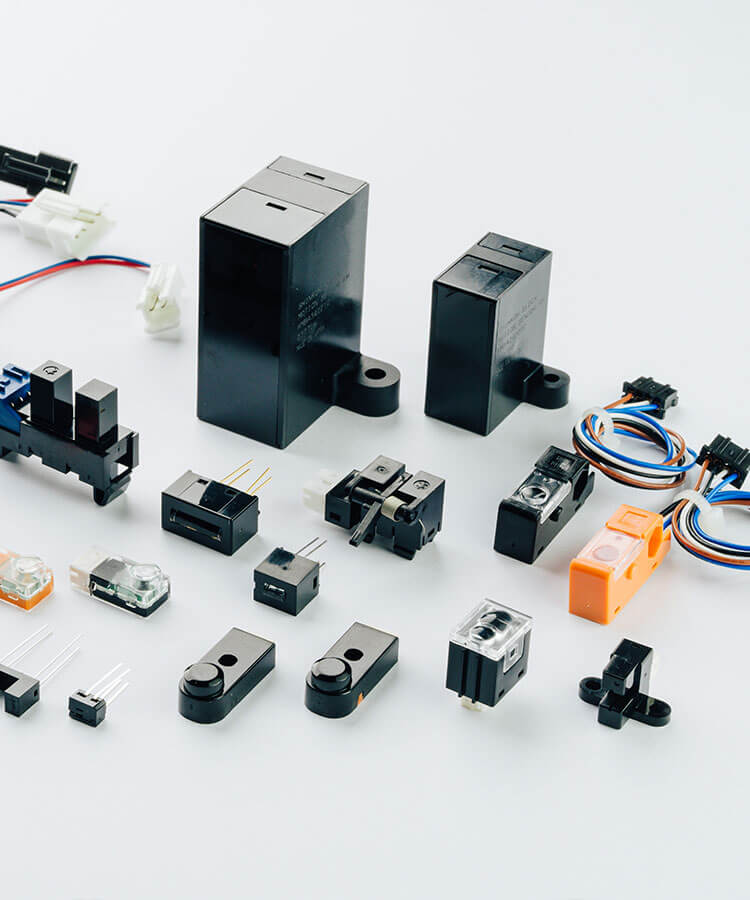

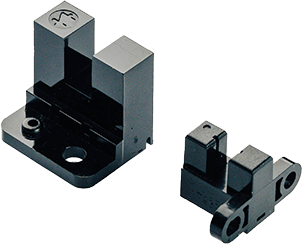

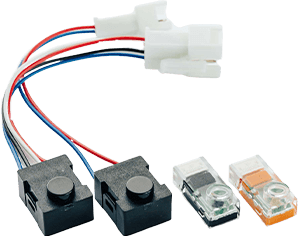

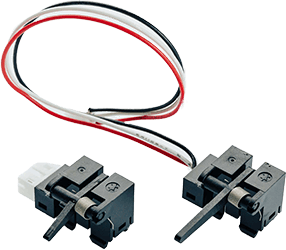

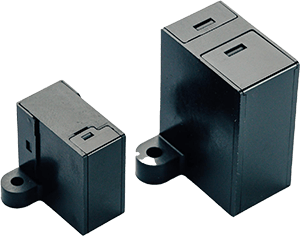

SERVICE Business Information

SHINKOH ELECTRONICS CO.,LTD.. is proud of our 50 years of the history since our founding as the photo sensor manufacturer. We lineup diverse and unique products by employing the technology of light cultivated over many years. We handle not only own products but also wide-ranging and high-quality products of the world’s manufacturers. We also customize existing products and reproduce discontinued products. Please feel free to contact us.

SHINKOH ELECS

PhotoSensores,

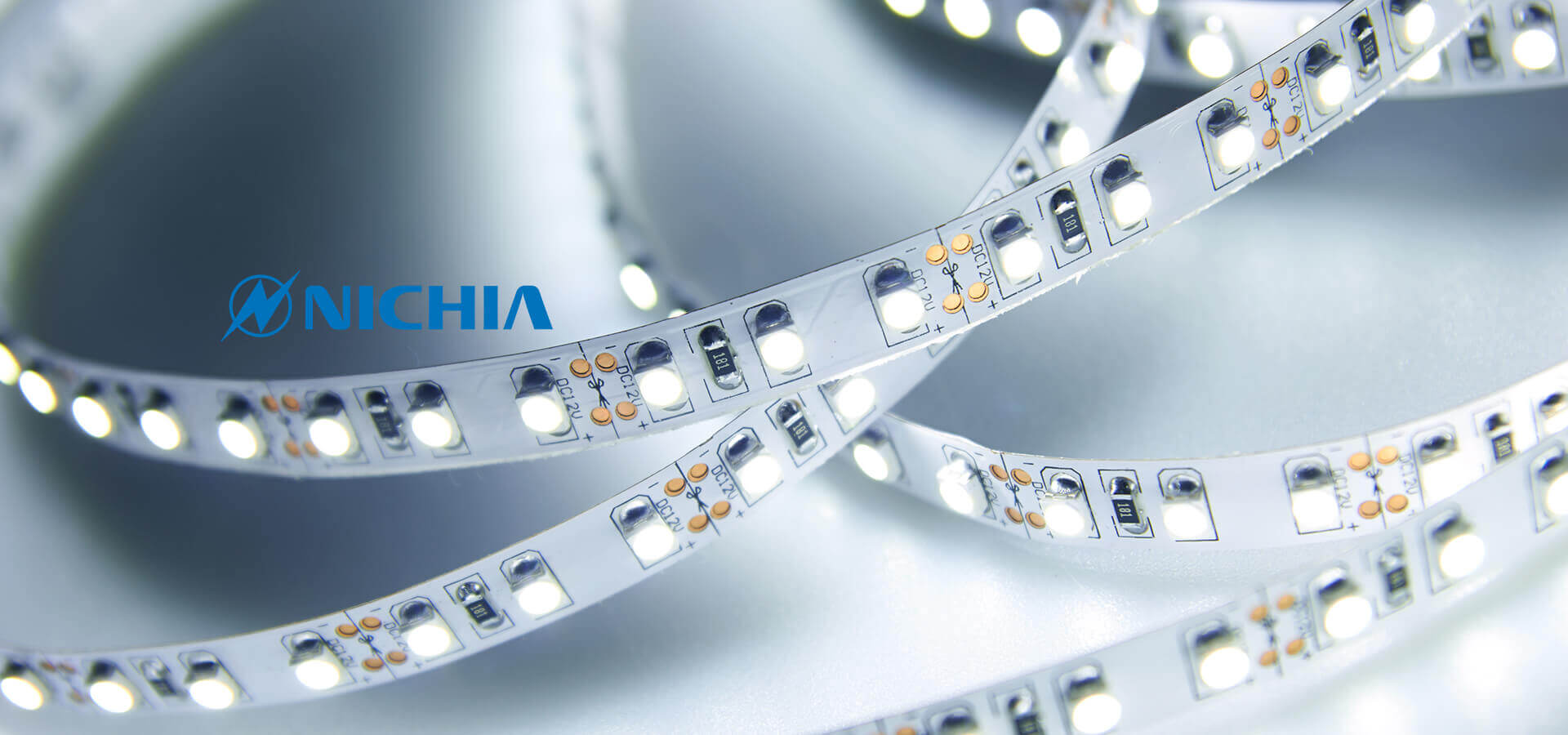

Agency Sales

-

Distribute for Japanese market only. The high-quality LED utilized in various scenes in the society such as the illumination, the safety device and the medical industry.

-

Distribute for Japanese market only.

The leading company continuing to lead the industry of DC motor drive system.

New Product List

PRODUCT

-

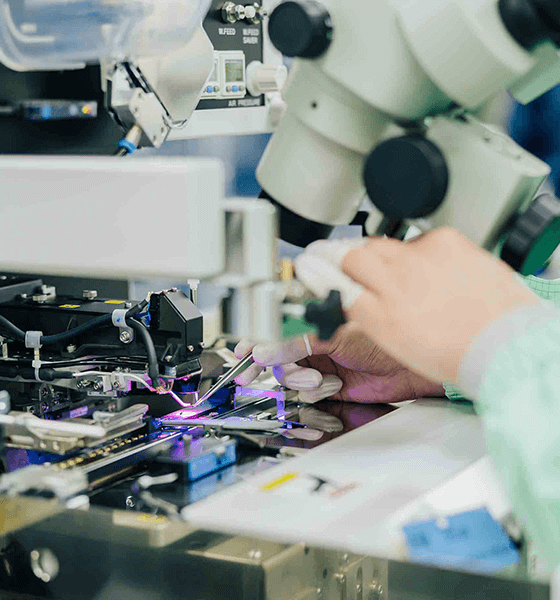

TECHNOLOGY SHINKOH ELECTRONICS

CO.,LTD.. TECHNOLOGYSHINKOH ELECTRONICS CO.,LTD.. builds up diverse know-how of the optical semiconductor including the photo sensor after 50 years of the business. We worked on manufacturing of the special wavelength LED from early on, produced the customized photo sensor with our knowledge and the original photo sensor which is as many as the world’s top class, and built the reliable brand “SHINKOH-ELECS”.

-

CORRESPONDENCE

SHINKOH ELECTRONICS CO.,LTD..

3responsiveness

SHINKOH ELECTRONICS CO.,LTD.. responds to the diverse needs of our customers with "3responsiveness" Please feel free to contact us if you have any concerns such as

``I can't find a product that meets your desired specifications'' or ``My development was rejected by another company.''

-

COMPANY Corporate profile

Shinkoh electronics was established in 1974.

We devoted ourselves to development and production, the sale of the optical sensor.

We would like to be the best partner of customers…

We are going to keep catching the highest technical information and application sensitively from all over the world, and work on technology development of the new age aiming at the realization of the new opto-century. -